Подробнее о продукте

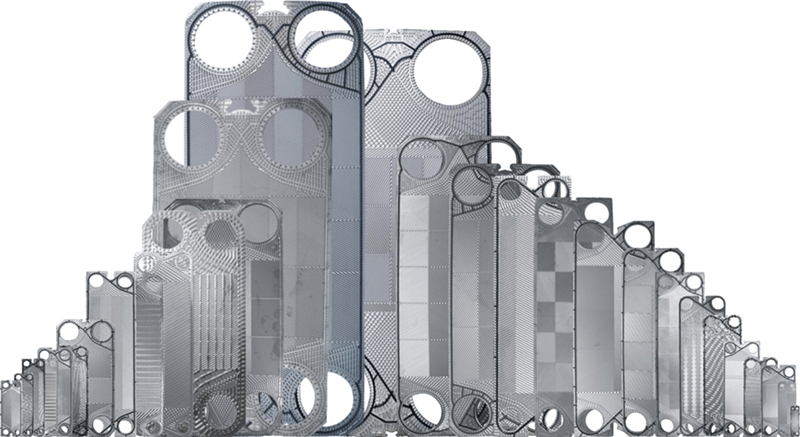

Пластинчатый теплообменник с шипованной насадкой

Design pressure: 3.6MPa

Design Temp: 210℃

Plate thickness : 0.4~1.0mm

Plate material: 304, 316L, 904L, 254SMO, Duplex SS, Titanium, C-276 etc.

Gasket material: EPDM, NBR, Viton, PTFE cushion etc.

Certificates: ASME, CE, BV, SGS etc.

Поделиться этим пунктом :

Подробнее о продукте

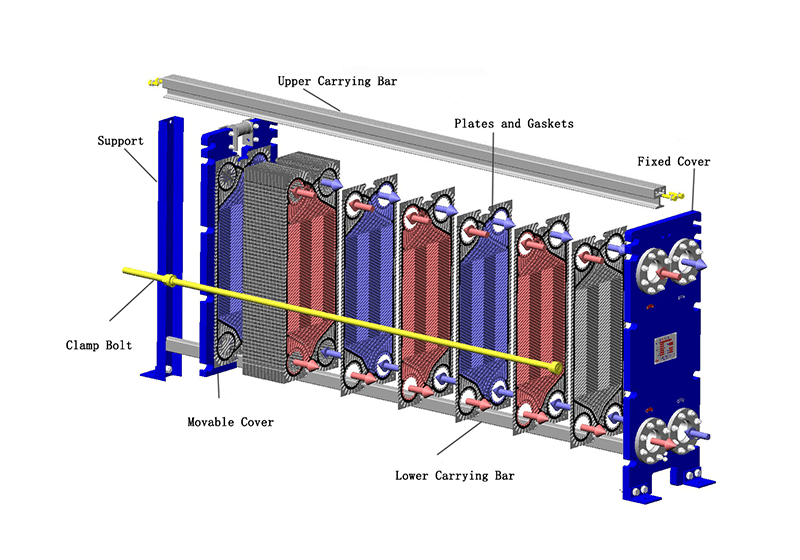

How Plate Heat Exchanger works?

Plate Heat Exchanger is composed of many heat exchange plates which are sealed by gaskets and tightened together by tie rods with locking nuts between frame plate. The medium runs into the path from the inlet and is distributed into flow channels between heat exchange plates. The two fluids flow countercurrent in the channel, the hot fluid transfers heat to the plate, and the plate transfers heat to the cold fluid on the other side. Therefore the hot fluid is cooled down and the cold fluid is warmed up.

Why plate heat exchanger?

☆ High heat transfer coefficient

☆ Compact structure less foot print

☆ Convenient for maintenance and cleaning

☆ Low fouling factor

☆ Small end-approach temperature

☆ Light weight

☆ Small footprint

☆ Easy to change surface area

Parameters

| Plate thickness | 0.4~1.0mm |

| Max. design pressure | 3.6MPa |

| Max. design temp. | 210ºC |

Контакты

Наши продукты

Наша основная ценность - надежность, высокая эффективность и профессионализм. Мы стремимся быть надежным партнером №1 в области трубопроводов и промышленных решений для клиентов по всему миру.

- Котел

- Пакет EPC (фитинги, фланцы)

- Применение в оффшорной зоне

- Нефть & Газопровод

- Нефтехимия

- Оребренная труба

- Котельный продукт

- Сборка труб

- Пластинчатый теплообменник

- Фланец

- Стальные трубы